Orient Filter Industries – Premier Food and Beverage Filter Manufacturers

What is a Food & Beverage Filter?

A food and beverage filter is a specialized filtration system designed to remove contaminants, particles, and impurities from liquids and gases used in food and beverage production. These filters ensure the purity, quality, and safety of the products while maintaining compliance with food-grade standards such as FDA and ISO certifications.

Types of Filtration Stages

Pre-Filtration: Removes large particles and sediments from raw materials.

Fine Filtration: Eliminates smaller particles, including microorganisms, to ensure product purity.

Polishing Filtration: Enhances the clarity and final quality of the beverage or food product.

Sterile Filtration: Removes bacteria, yeast, and other pathogens to ensure safety.

How Food & Beverage Filters Work

The filtration process involves passing liquids or gases through a series of filter media.

These media trap contaminants of different sizes and types at various stages.

Depending on the filter type, materials such as activated carbon, synthetic membranes, or stainless steel mesh are used.

The process may include pre-filtration, microfiltration, and sterilization to ensure a high-quality final product.

How to Choose a Food & Beverage Filter

Micron Rating:

Choose a filter with the appropriate micron rating based on the size of particles to be removed. Fine filters with ratings as low as 0.2 microns are ideal for sterile filtration.

Types:

Select filters based on application needs, such as cartridge filters for liquids or activated carbon filters for odor and taste removal.

Water Quality:

Assess the quality of the water or raw material being filtered. High turbidity or chemical content may require multiple filtration stages.

Backwashing:

Consider filters with backwashing capabilities to clean the media and maintain performance without frequent replacements.

Benefits of Food & Beverage Filters

Ensures product purity and safety.

Enhances the taste, clarity, and appearance of beverages.

Reduces operational costs through efficient and reliable filtration.

Extends the shelf life of food and beverage products.

Protects downstream equipment from damage caused by contaminants.

Advantages of Food & Beverage Filters

Food-Grade Materials: Compliant with FDA and ISO certifications for food safety.

High Efficiency: Removes even the smallest contaminants, ensuring premium quality.

Customizable Designs: Tailored to meet the specific needs of your production process.

Durable Construction: Built to withstand harsh operating conditions.

Cost-Effective: Long-lasting filters with minimal maintenance needs.

Applications of Food & Beverage Filters

Water Filtration: For beverage production like juices, sodas, and bottled water.

Dairy Industry: Used for milk, cheese, and yogurt processing.

Brewing: Filters for beer and wine production to ensure clarity and taste.

Edible Oils: Removes impurities from cooking oils.

Food Processing: Filters for sauces, soups, and other liquid food items.

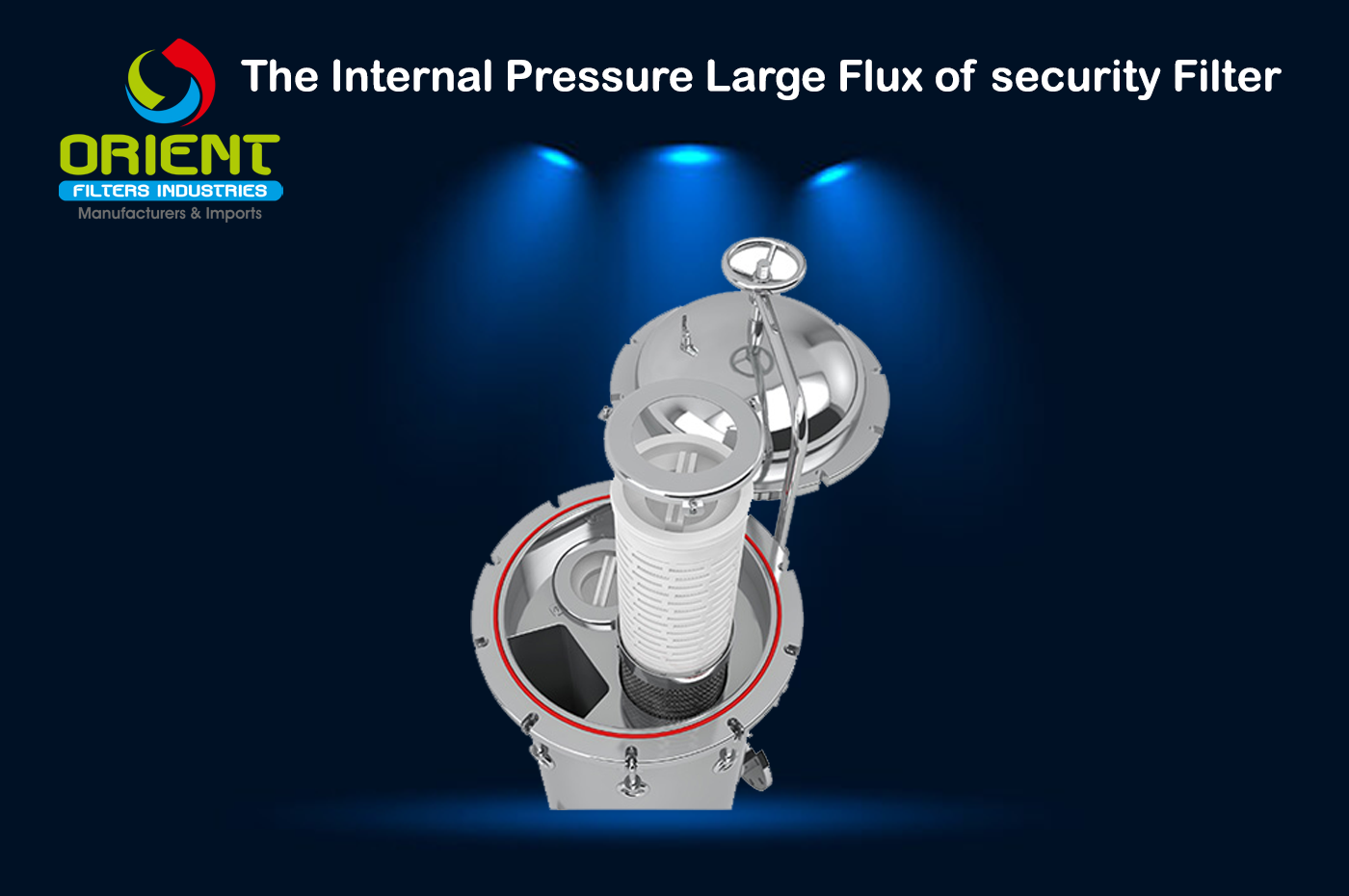

Features of Food & Beverage Filters

High Filtration Precision: Capable of filtering particles as small as 0.2 microns.

Sanitary Design: Built to maintain hygienic conditions during filtration.

Corrosion-Resistant Materials: Stainless steel or polymer construction for durability.

Easy Maintenance: Simple cleaning and replacement processes.

Custom Configurations: Available in various sizes and configurations for specific needs.

What is Removed from Food & Beverage Filters?

Sediments: Sand, dirt, and rust particles.

Microorganisms: Bacteria, yeast, and fungi.

Organic Compounds: Pesticides, VOCs, and other harmful chemicals.

Chlorine and Odors: Ensures taste and smell remain unaffected.

Oils and Greases: Improves the clarity and safety of the product.

Industry to Use

Beverage Production: Water, soda, juice, and alcoholic drinks.

Dairy Industry: Milk, cream, and cheese production.

Food Processing: Ready-to-eat sauces, soups, and oils.

Brewing and Distillation: Beer, wine, and spirits production.

Packaged Food Manufacturers: Ensures long shelf life and safety.

Specifications

Category: Food and Beverage Filtration Systems.

Temperature: Operates effectively in temperatures up to 80°C.

Diameter: Customizable based on system requirements.

Rating: Ranges from 0.2 microns for sterile filtration to 50 microns for pre-filtration.

Length: Available in various lengths up to 1000 mm.

Shape: Cylindrical, rectangular, or customized designs.

Size: Tailored to production scale.

Capacity: Designed for small-scale to large industrial filtration requirements.

Why Choose Orient Filter Industries Food & Beverage Filters?

Unmatched Quality: We use food-grade materials compliant with global standards.

Tailored Solutions: Customizable designs to meet unique industrial challenges.

Reliable Performance: Efficient and long-lasting filtration for consistent results.

Comprehensive Support: Dedicated after-sales support and technical guidance.

Experience: Trusted by top food and beverage manufacturers worldwide.

With Orient Filter Industries, you can trust our expertise to deliver superior food and beverage filters that guarantee the purity, safety, and quality of your products. Let us enhance your production process with our innovative filtration solutions!

Conventional Filter Cartridge Series

Conventional Filter Cartridge Series High Flow Filter Cartridge Series

High Flow Filter Cartridge Series Industry Housing Products Series

Industry Housing Products Series Resin Bonded Filter

Resin Bonded Filter Sintered Filter Cartride

Sintered Filter Cartride SS-Pleated and Mess Filter

SS-Pleated and Mess Filter PP Pleated Filter

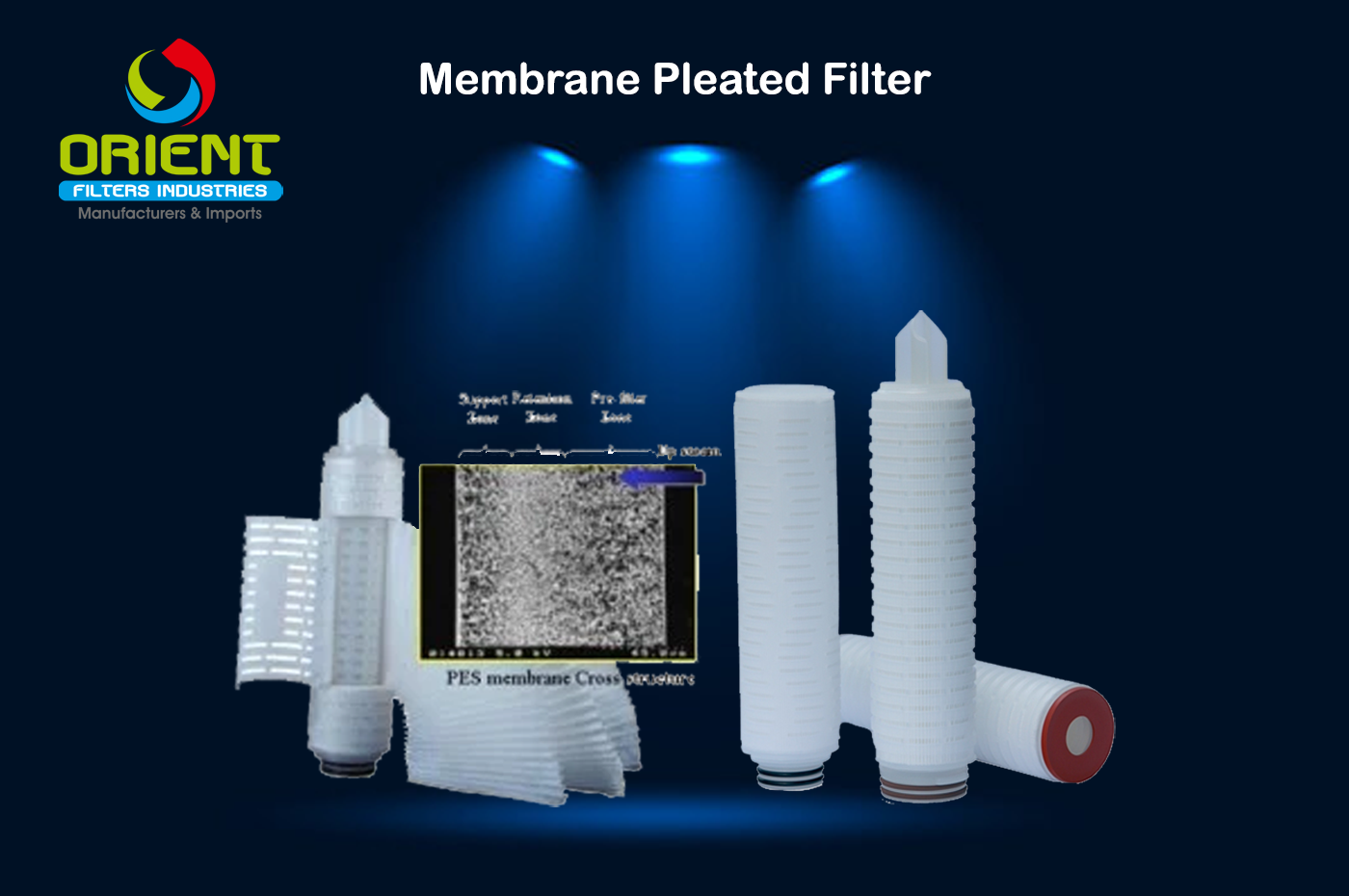

PP Pleated Filter Membrane Pleated Filter

Membrane Pleated Filter TS Series Single Cartridge Filter Housing

TS Series Single Cartridge Filter Housing High Flow Filter

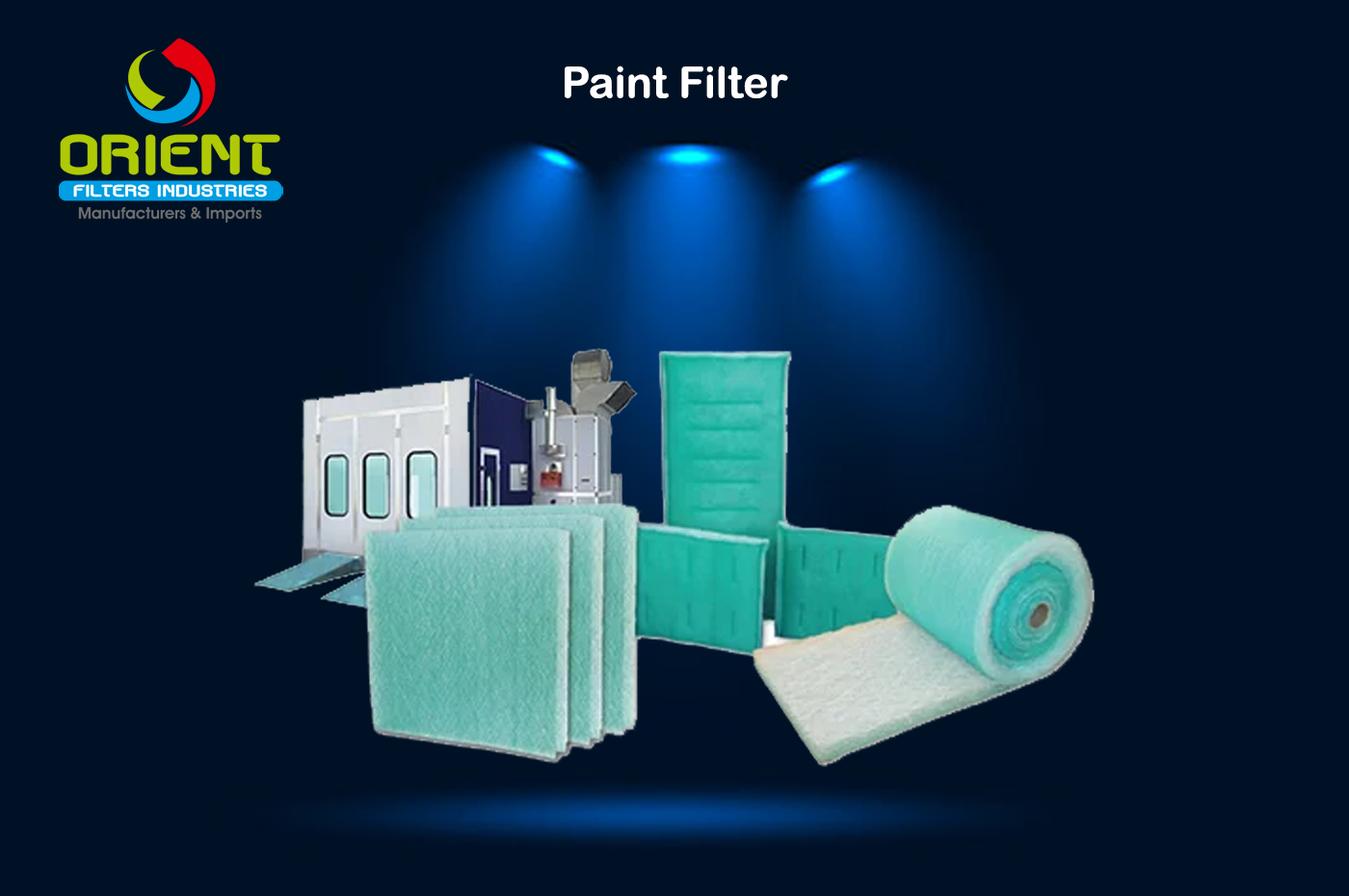

High Flow Filter Paint Filter

Paint Filter Oil Filter

Oil Filter Hydraulic Oil Filter

Hydraulic Oil Filter Air Filter

Air Filter Gear System For Fitting

Gear System For Fitting spun Filters

spun Filters AHU Filter

AHU Filter Bag Filter

Bag Filter Capsule Filter

Capsule Filter Carbon Filter

Carbon Filter Chemical Filter

Chemical Filter Compressors Filter

Compressors Filter Food Beverage Filter

Food Beverage Filter Media Filter

Media Filter Pharmacy Filter

Pharmacy Filter Reverse Osmosis

Reverse Osmosis