Orient Filter Industries – Leading Chemical Filter Manufacturers

What is a Chemical Filter?

A chemical filter is a specialized filtration system designed to remove impurities, contaminants, and hazardous substances from chemical solutions or industrial processes. These filters ensure product purity, process efficiency, and safety in handling chemicals across various industries.

Types of Chemical Filters

Activated Carbon Filters: Removes organic compounds, odors, and unwanted gases.

Cartridge Filters: Efficient in filtering fine particles and sediments.

Bag Filters: Ideal for bulk filtration of liquids with larger contaminants.

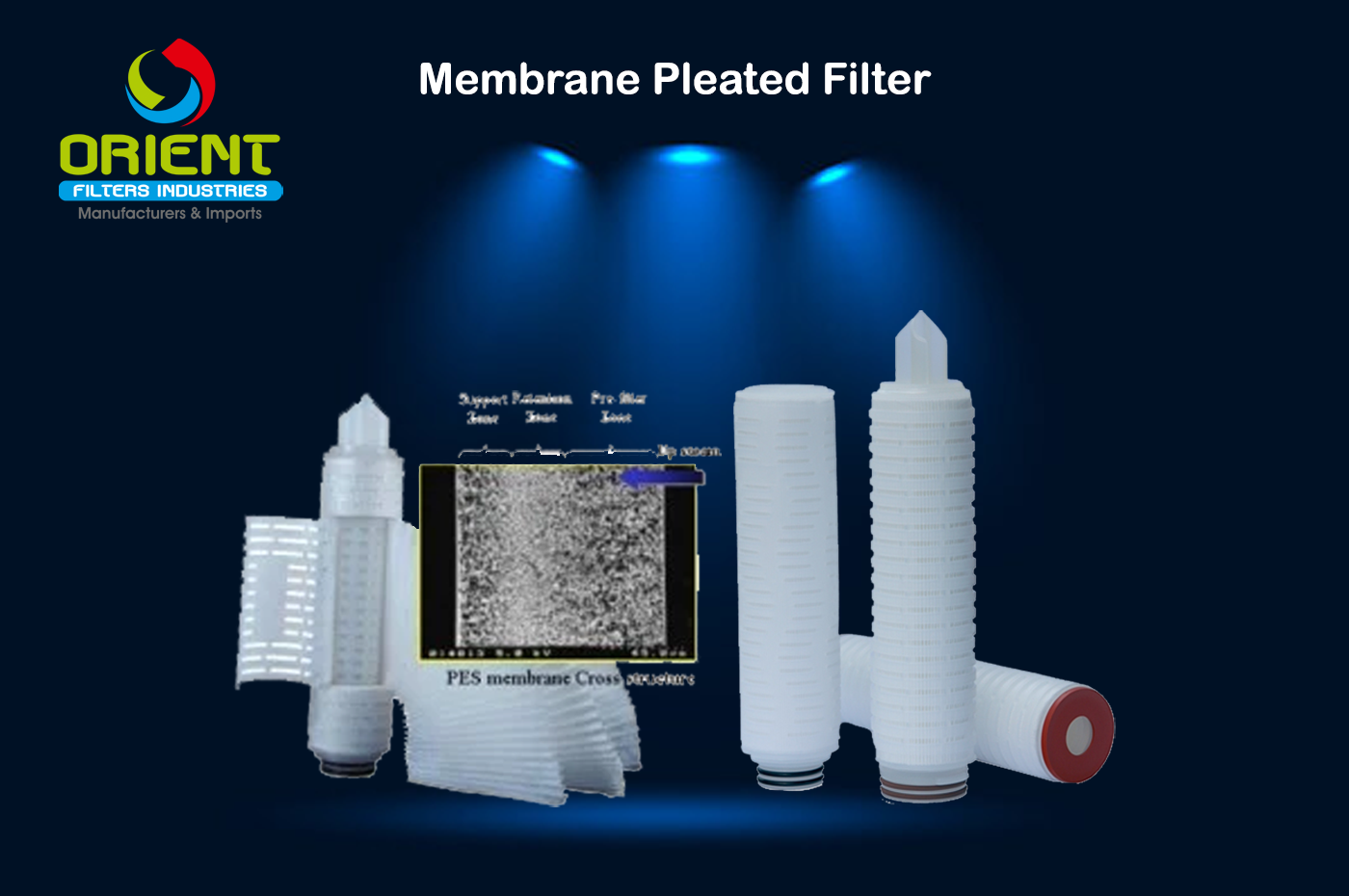

Membrane Filters: Suitable for microfiltration and ultrafiltration applications.

Ion Exchange Filters: Used for deionizing and softening water in chemical processes.

Uses of Chemical Filters

Water Treatment: Removing contaminants from industrial wastewater.

Chemical Manufacturing: Ensuring purity during production processes.

Pharmaceuticals: For sterile filtration in drug manufacturing.

Petrochemical Industry: Filtering hydrocarbons and refining processes.

Food and Beverage: Removing residual chemicals from processing water.

How Chemical Filters Work?

Chemical filters function by passing liquid or gas through a specialized media that traps or neutralizes contaminants.

Physical Filtration: Removes particles like sediments and solids.

Chemical Adsorption: Absorbs unwanted gases, odors, and organic compounds.

Ion Exchange: Replaces harmful ions with benign ones for water treatment.

Membrane Separation: Filters microscopic particles and pathogens.

Advantages of Chemical Filters

Improved Safety: Removes hazardous substances, reducing risks.

Enhanced Purity: Ensures high-quality chemical outputs.

Cost-Efficient: Reduces waste and operational costs.

Versatility: Suitable for a wide range of applications and industries.

Eco-Friendly: Minimizes environmental impact through effective filtration.

Applications of Chemical Filters

Industrial Processing: Filtration of chemicals, solvents, and acids.

Pharmaceutical Production: Sterile filtration and contaminant removal.

Petroleum Refining: Ensures purity in fuel and lubricant production.

Water Treatment Plants: Removes chemicals and impurities from water.

Food and Beverage Industry: Eliminates chemical residues from water and other inputs.

Features of Chemical Filters

High Filtration Accuracy: Removes particles down to 0.1 microns.

Chemical Resistance: Built to withstand corrosive substances.

Durable Design: Constructed from high-quality materials like stainless steel or polypropylene.

Easy Maintenance: Quick and simple cleaning or replacement of filter media.

Customizable Solutions: Available in various sizes and configurations.

How to Choose the Right Chemical Filter

Micron Rating:

Select filters with appropriate micron ratings based on application needs. A lower rating is essential for fine filtration, while higher ratings suffice for pre-filtration.

Types:

Choose from cartridge, bag, or activated carbon filters based on the type of contaminants.

Water Quality:

Evaluate the chemical composition and impurities in the fluid to determine the right filter media.

Backwashing:

Opt for filters with backwashing capabilities for continuous operation and reduced maintenance.

What is Removed from Chemical Filters?

Solids and Sediments: Sand, rust, and debris.

Organic Compounds: Oils, greases, and solvents.

Chemical Impurities: Hazardous ions, toxins, and corrosive chemicals.

Pathogens: Bacteria, viruses, and fungi in sensitive applications.

Step-by-Step Chemical Filtration Process

Pre-Filtration: Removes large particles and sediments.

Primary Filtration: Traps finer particles and chemical impurities using activated carbon or membranes.

Polishing Filtration: Ensures final clarity and quality of the output.

Drainage: Disposes of collected contaminants safely.

Industries to Use

Chemical Manufacturing

Pharmaceuticals

Petrochemicals

Food and Beverage

Water Treatment

Electronics Manufacturing

Specifications

Motor Power: Compatible with pumps ranging from 1 HP to 500 HP.

Max Pressure: Up to 20 bar (290 psi) for high-pressure operations.

Max Temperature: Withstands temperatures up to 100°C.

Max Flow: Customizable flow rates for various process needs.

Max Capacity Range: Supports small to large-scale operations.

Compressor Type: Not applicable; designed for filtration units.

Category: Cartridge, bag, activated carbon, and membrane filters.

Diameter: Configurable to match system requirements.

Rating: Filtration precision as low as 0.1 microns.

Length: Customizable sizes available.

Shape: Cylindrical, rectangular, or tailored designs.

Size: Standard and bespoke dimensions.

Why Choose Orient Filter Industries Chemical Filters?

Exceptional Quality: Manufactured with premium-grade materials for durability.

Innovative Technology: Incorporates advanced designs for superior filtration.

Custom Solutions: Tailored to meet unique industrial challenges.

Global Standards: Compliant with ISO, CE, and FDA certifications.

Proven Expertise: Trusted by leading companies across various industries.

Comprehensive Support: Dedicated after-sales service and technical guidance.

With Orient Filter Industries, experience unparalleled filtration solutions designed for efficiency, reliability, and safety in chemical processing.

Conventional Filter Cartridge Series

Conventional Filter Cartridge Series High Flow Filter Cartridge Series

High Flow Filter Cartridge Series Industry Housing Products Series

Industry Housing Products Series Resin Bonded Filter

Resin Bonded Filter Sintered Filter Cartride

Sintered Filter Cartride SS-Pleated and Mess Filter

SS-Pleated and Mess Filter PP Pleated Filter

PP Pleated Filter Membrane Pleated Filter

Membrane Pleated Filter TS Series Single Cartridge Filter Housing

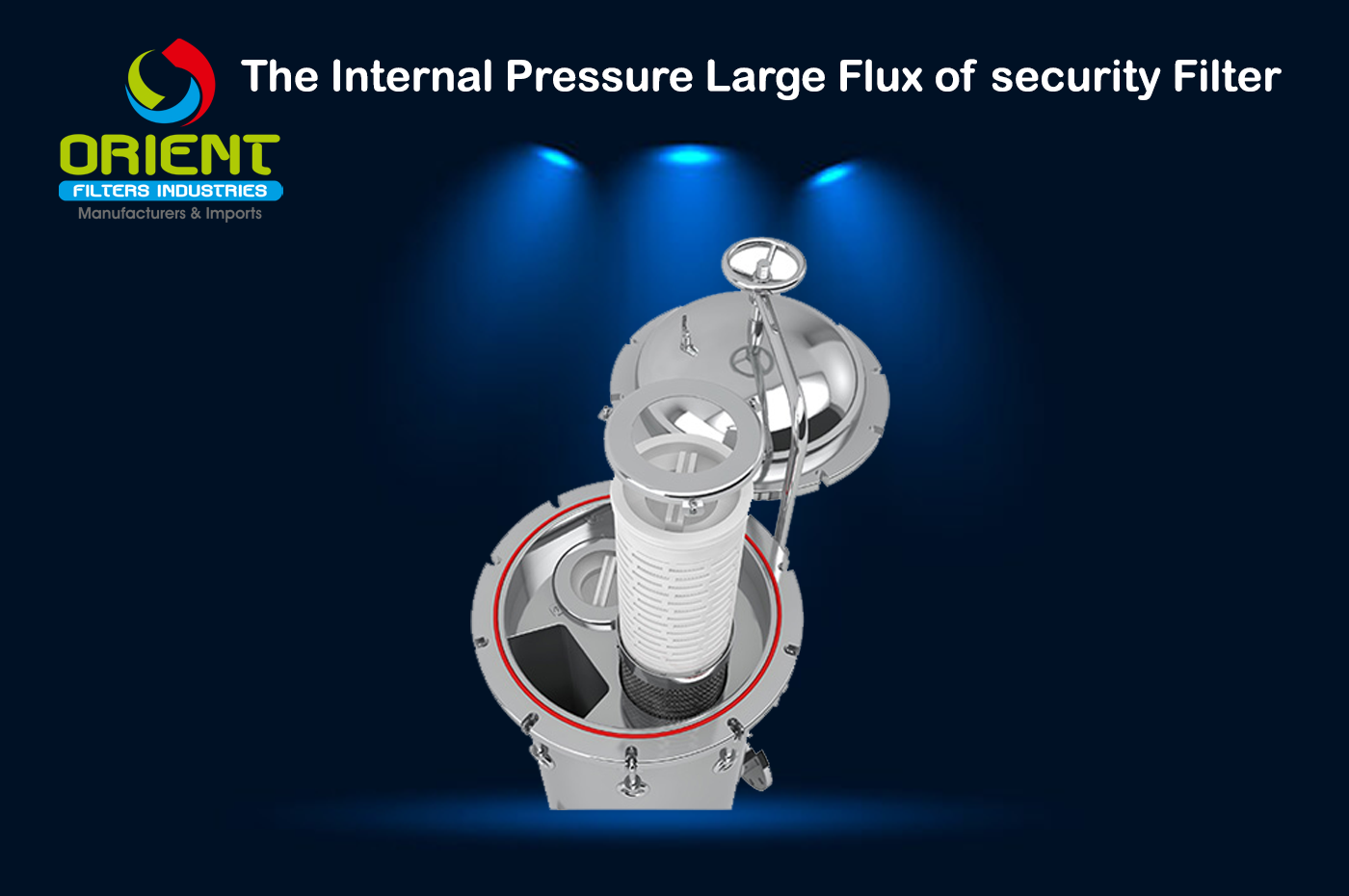

TS Series Single Cartridge Filter Housing High Flow Filter

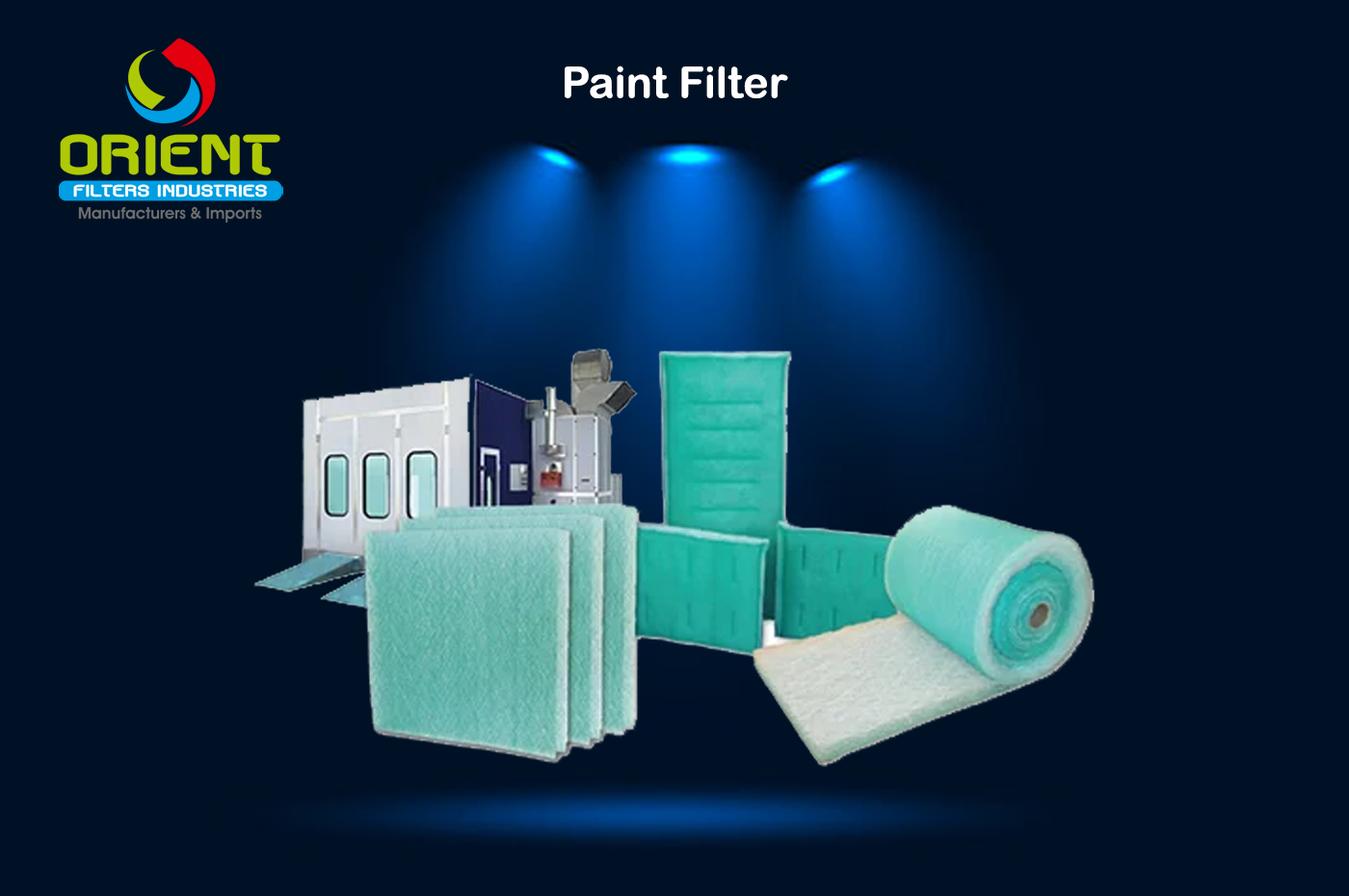

High Flow Filter Paint Filter

Paint Filter Oil Filter

Oil Filter Hydraulic Oil Filter

Hydraulic Oil Filter Air Filter

Air Filter Gear System For Fitting

Gear System For Fitting spun Filters

spun Filters AHU Filter

AHU Filter Bag Filter

Bag Filter Capsule Filter

Capsule Filter Carbon Filter

Carbon Filter Chemical Filter

Chemical Filter Compressors Filter

Compressors Filter Food Beverage Filter

Food Beverage Filter Media Filter

Media Filter Pharmacy Filter

Pharmacy Filter Reverse Osmosis

Reverse Osmosis