Orient Filter Industries – Expert Air Compressor Filter Manufacturers

What is an Air Compressor Filter?

An air compressor filter is a device designed to remove impurities, contaminants, and unwanted particles from compressed air. These filters ensure clean and high-quality compressed air, which is crucial for the efficient functioning of machinery and maintaining product quality in industrial processes.

Types of Filtration Stages

Pre-Filtration: Captures large particles like dust and debris.

Coalescing Filtration: Removes oil and water aerosols from compressed air.

Activated Carbon Filtration: Eliminates odors and vapors, ensuring clean air.

Particulate Filtration: Filters out fine dust and microorganisms for sterile applications.

Types of Air Compressor Filters

Particulate Filters: Removes solid contaminants like dust, dirt, and rust.

Coalescing Filters: Separates oil and water droplets from compressed air.

Activated Carbon Filters: Removes oil vapors, odors, and hydrocarbon traces.

High-Pressure Filters: Designed for systems operating under high-pressure conditions.

Dry Filters: Ensures completely moisture-free air.

How Air Compressor Filters Work

Compressed air enters the filter and passes through various filtration media.

Particulate Filters: Trap solid particles using a mesh or pleated material.

Coalescing Filters: Combine small oil and water droplets into larger ones, which are then drained out.

Activated Carbon Filters: Absorb vapors, odors, and hydrocarbons using a porous carbon material.

The result is clean, dry, and contaminant-free compressed air suitable for industrial or commercial use.

How to Choose the Right Air Compressor Filter

Micron Rating:

Select a filter with the appropriate micron rating. A lower micron rating (e.g., 0.1 microns) is ideal for sterile or sensitive applications, while a higher rating works for general purposes.

Types:

Choose a filter based on specific needs such as particulate, coalescing, or carbon filtration.

Water Quality:

If moisture content is high in compressed air, opt for coalescing or desiccant filters.

Backwashing:

For systems requiring frequent cleaning, consider filters with backwashing capabilities to maintain consistent performance.

Benefits/Advantages of Air Compressor Filters

Protects Equipment: Prevents damage caused by contaminants in compressed air systems.

Enhances Product Quality: Ensures clean air for sensitive industrial applications.

Reduces Maintenance Costs: Minimizes wear and tear on downstream equipment.

Improves Efficiency: Enhances the performance and longevity of compressors and tools.

Compliant with Standards: Meets safety and quality standards for industrial air systems.

Applications of Air Compressor Filters

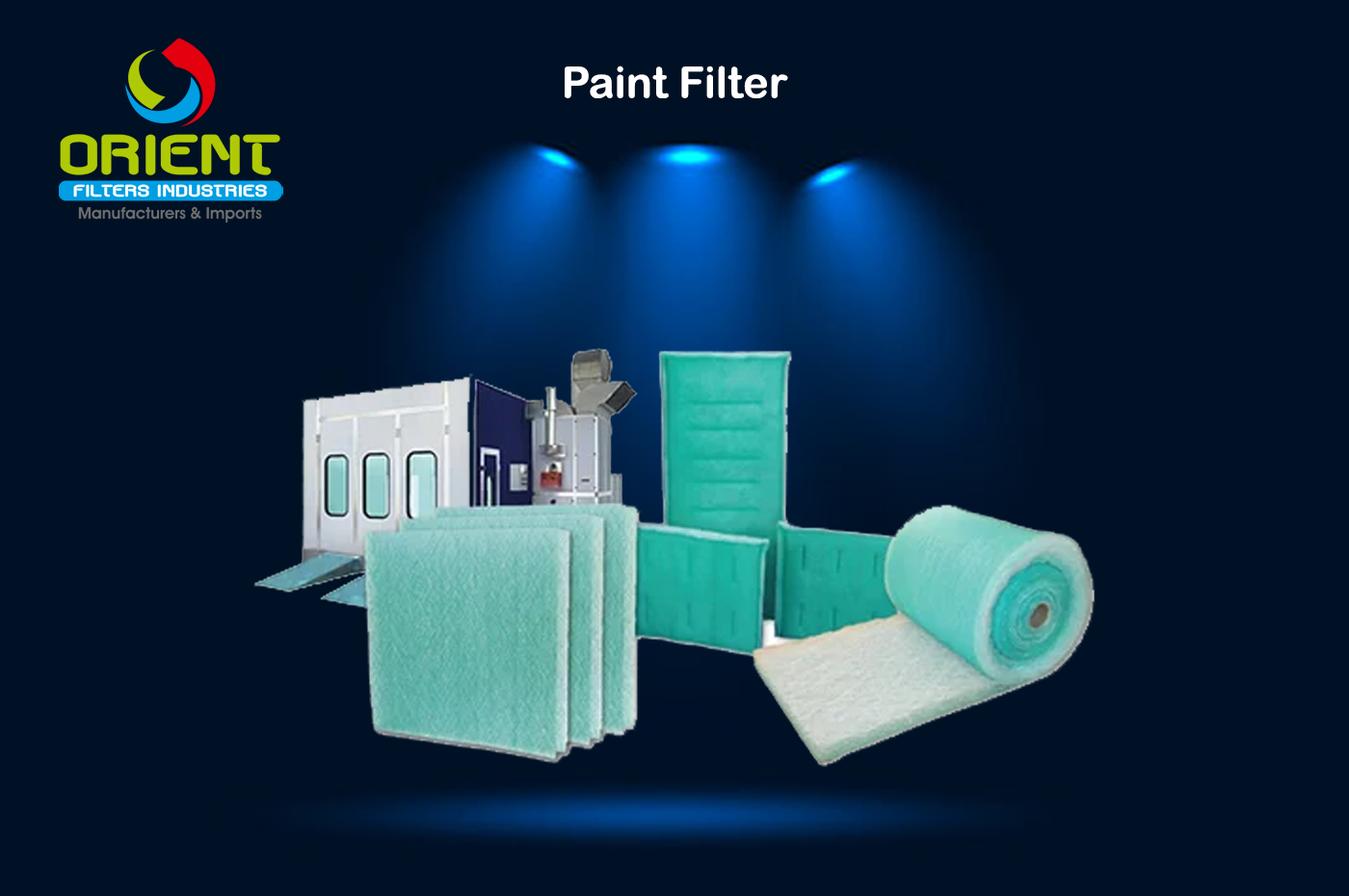

Automotive Industry: For spray painting and pneumatic tools.

Food and Beverage: Ensures clean air for food processing and packaging.

Pharmaceuticals: Maintains sterile environments and processes.

Electronics Manufacturing: Removes moisture and particles to protect sensitive components.

Chemical Processing: Ensures contamination-free air for chemical production.

HVAC Systems: Improves air quality in ventilation systems.

Features of Air Compressor Filters

High Filtration Efficiency: Removes up to 99.99% of contaminants.

Robust Construction: Made from durable materials like stainless steel and aluminum.

Low Pressure Drop: Ensures efficient air flow with minimal energy loss.

Easy Maintenance: Simple cleaning and replacement of filter elements.

Customizable: Available in various sizes and configurations for specific applications.

What is Removed from Air Compressor Filters?

Dust and Dirt: Particles that can damage equipment and reduce air quality.

Oil Mist: Residual oil that can contaminate products or processes.

Water Vapor: Moisture that can lead to corrosion and equipment failure.

Microorganisms: Bacteria and spores that can compromise product integrity.

Odors and Vapors: Hydrocarbon traces and unpleasant smells.

Problems Caused by Compressed Air Contamination

Corrosion: Moisture in compressed air can corrode pipelines and equipment.

Reduced Efficiency: Contaminants can clog systems, leading to inefficiencies.

Product Contamination: Affects quality and safety in food, beverage, and pharmaceutical industries.

Equipment Damage: Increases wear and tear on pneumatic tools and machinery.

Industry to Use

Automotive

Food and Beverage

Pharmaceuticals

Electronics Manufacturing

Chemical Processing

Textiles

Construction

Specifications

Motor Power: Compatible with compressors ranging from 1 HP to 500 HP.

Max Pressure: Up to 16 bar (232 psi) or higher for specialized filters.

Max Temperature: Operates efficiently in temperatures up to 80°C.

Max Flow: Customizable flow rates for different industrial requirements.

Max Capacity Range: Designed to handle small-scale to large industrial systems.

Compressor Type: Suitable for rotary screw, piston, and centrifugal compressors.

Category: Particulate, coalescing, and activated carbon filters.

Diameter: Customizable based on system requirements.

Rating: Available in micron ratings as low as 0.01 microns.

Length: From standard sizes to customized lengths.

Shape: Cylindrical, rectangular, or custom designs.

Size: Standard or tailored to customer specifications.

Why Choose Orient Filter Industries Air Compressor Filters?

Unparalleled Quality: Manufactured using premium-grade materials for durability.

Advanced Technology: Incorporates innovative designs for optimal filtration.

Custom Solutions: Tailored to meet specific industry needs and applications.

Global Standards: Compliant with ISO, CE, and other international certifications.

Reliable Performance: Ensures consistent and efficient operation across various environments.

Comprehensive Support: Offers expert guidance and after-sales service.

At Orient Filter Industries, we provide superior air compressor filters that ensure clean, efficient, and reliable compressed air for your industrial needs. Trust us for performance and excellence in filtration technology.

Conventional Filter Cartridge Series

Conventional Filter Cartridge Series High Flow Filter Cartridge Series

High Flow Filter Cartridge Series Industry Housing Products Series

Industry Housing Products Series Resin Bonded Filter

Resin Bonded Filter Sintered Filter Cartride

Sintered Filter Cartride SS-Pleated and Mess Filter

SS-Pleated and Mess Filter PP Pleated Filter

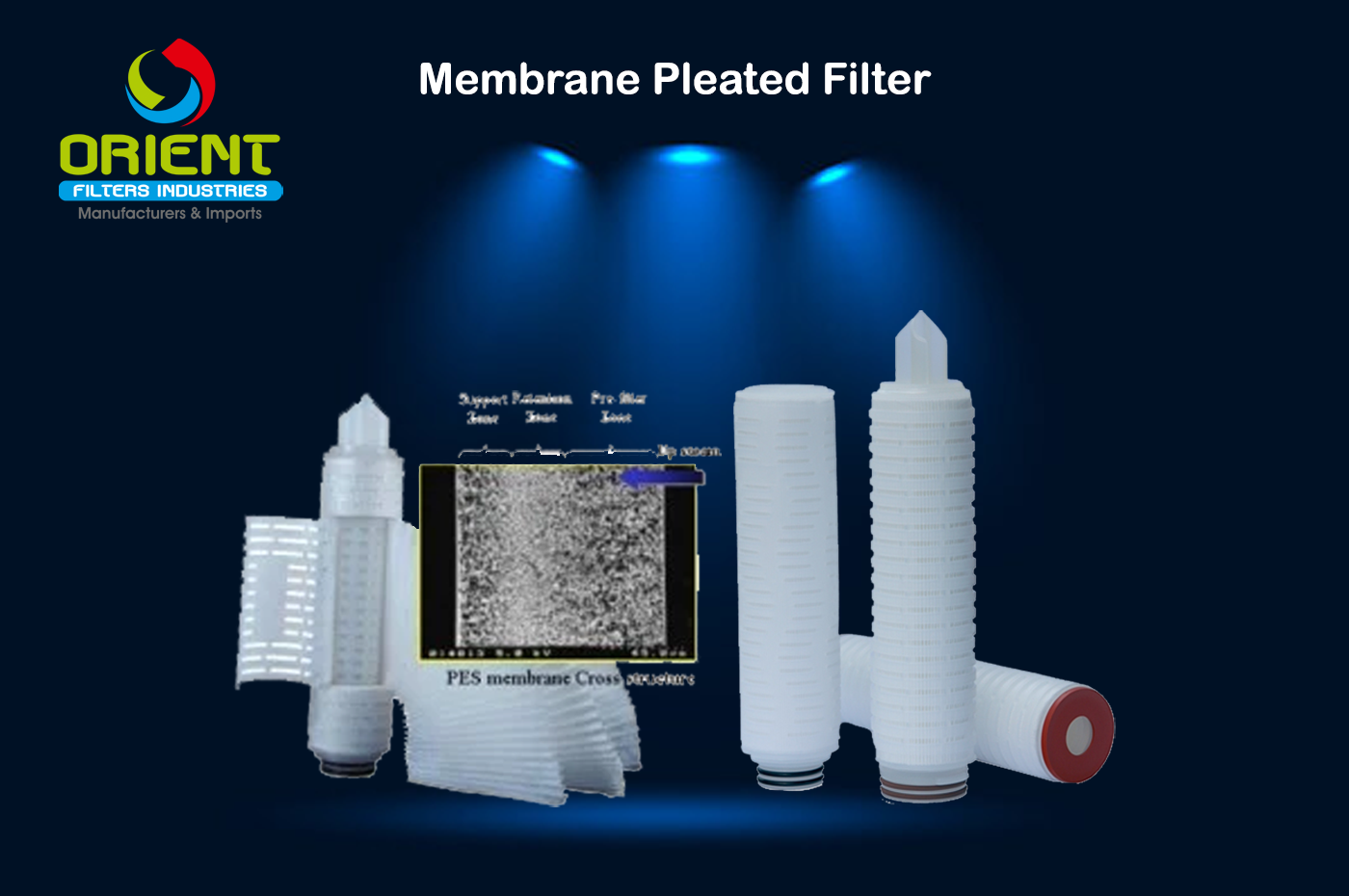

PP Pleated Filter Membrane Pleated Filter

Membrane Pleated Filter TS Series Single Cartridge Filter Housing

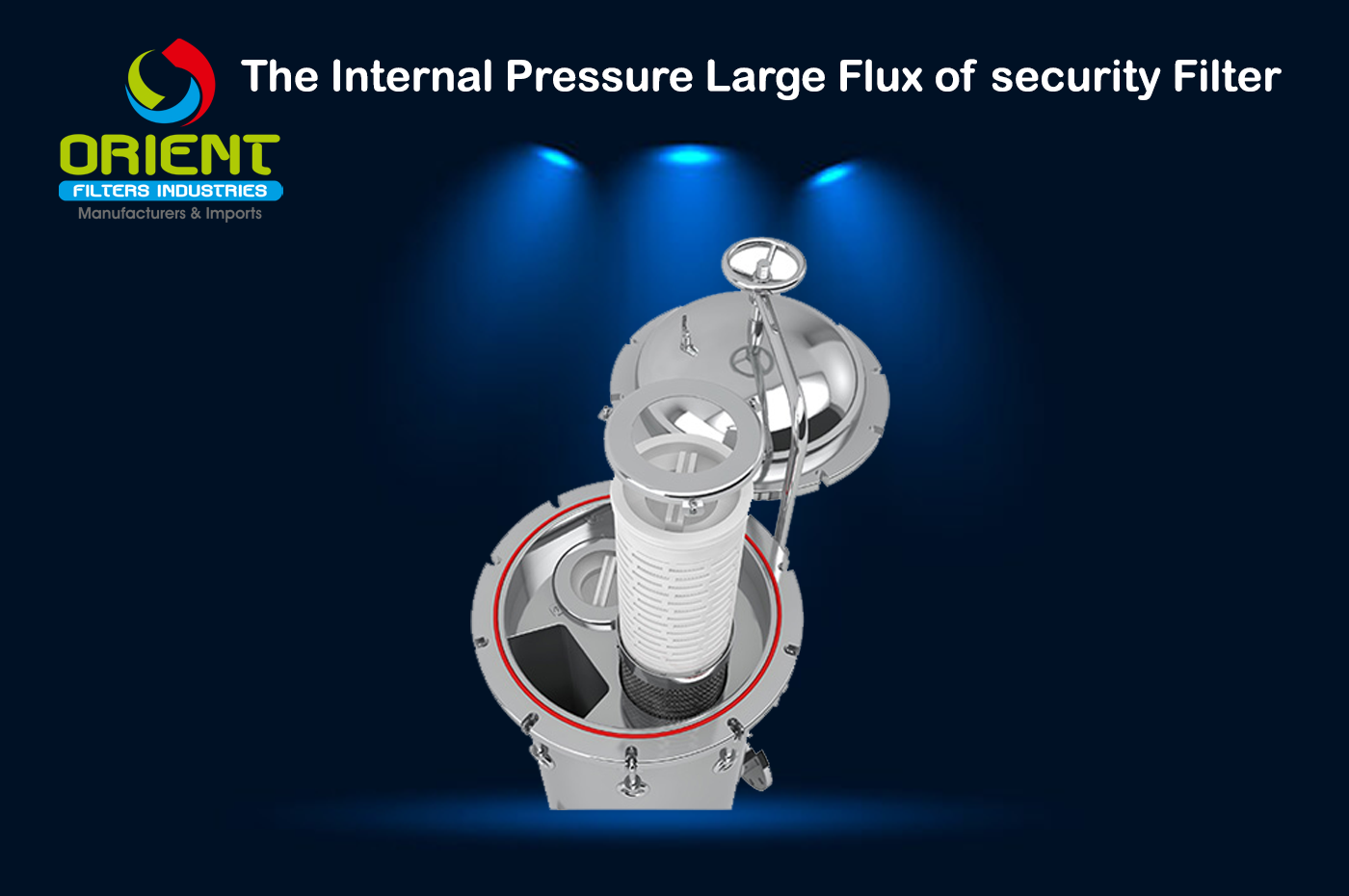

TS Series Single Cartridge Filter Housing High Flow Filter

High Flow Filter Paint Filter

Paint Filter Oil Filter

Oil Filter Hydraulic Oil Filter

Hydraulic Oil Filter Air Filter

Air Filter Gear System For Fitting

Gear System For Fitting spun Filters

spun Filters AHU Filter

AHU Filter Bag Filter

Bag Filter Capsule Filter

Capsule Filter Carbon Filter

Carbon Filter Chemical Filter

Chemical Filter Compressors Filter

Compressors Filter Food Beverage Filter

Food Beverage Filter Media Filter

Media Filter Pharmacy Filter

Pharmacy Filter Reverse Osmosis

Reverse Osmosis